StabilRoad

STABILROAD® IS STABLE AND DURABLE!

Modern civil engineering has been using cement as the main stabilizer due to its excellent bonding properties. But this does not work on clay, sandy and muddy soil. In such cases, besides better bonding, fill surfaces should be used. The problem with this is that the cement-treated soils become very rigid and the risk of surface cracking is very high.

By using the StabilRoad® cement additive in a corresponding amount along with prescribed proportion of cement, there will be no risk of cracking. This is due to its ability to change the parameters of the concrete’s bending strength. StabilRoad® is today one of the most advanced and technologically innovative soil stabilization material and technology in the world.

StabilRoad® is a whitish powder made of 100% natural minerals with no synthetic chemicals. STABILROAD® technology has been developed in Germany and has been used since 20 years in most of the world’s diffrent climate zones.

Consists of only 6 stages

Is scientifically proven

Meets the required conditions

Saves time and costs

Gives ecological preference

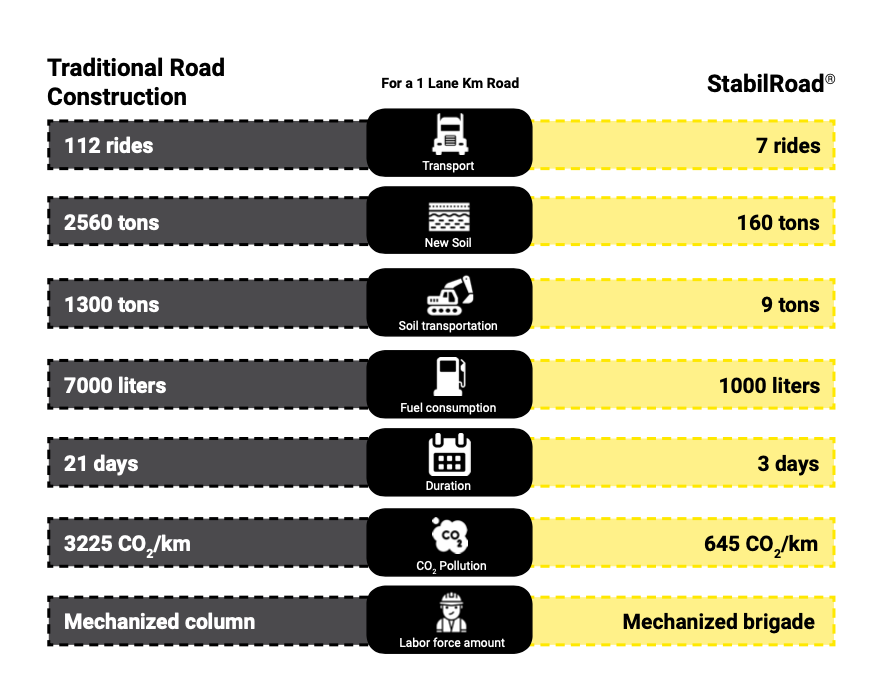

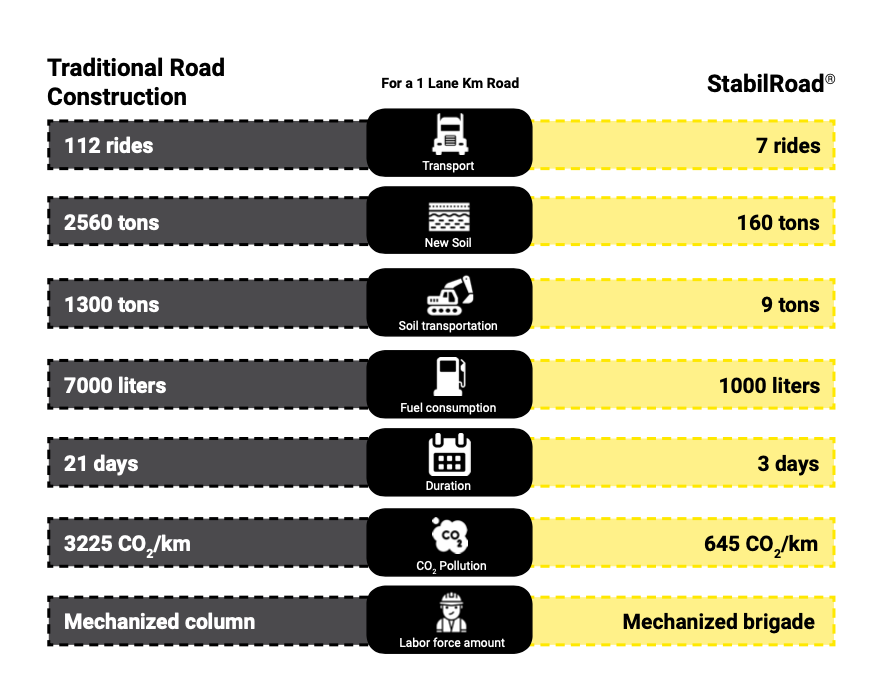

Traditional Road Construction vs StabilRoad®

STABILROAD® IS STABLE AND DURABLE!

INNOVATIVE

StabilRoad® is a modern and innovative soil stabilizing technology. The existing soils are processed with cement and special additive. This makes the soil very resistance to the compressive strength as well as elastic, waterproof and frost resistant.

HIGH QUALITY

The quality and warranty of StabilRoad® with over 20 years of experience on several continents, different climate zones and numerous soils of different types helps in great quality of construction of roads.

ECONOMICAL

Stabilizing is carried out on the layers of the existing soils, by mixing it with cement and StabilRoad® additive. On the contrary to the common road construction technology there is no need to dig out existing soil. We can utilise the existing soil or asphalt. We need not bring in new soils or aggregates to construct roads.

ECOLOGICAL ADVANTAGE

-

MINIMUM ENERGY/FOSSILfuel consumption

-

RECYCLING AND RE-USEof local soils and materials

-

REDUCTIONin emitting harmful exhaust gases to the surrounding environment

-

DECREASE IN NEGATIVE PUBLIC RESPONSEresulting from the high-volume transport of huge inert materials

-

NATURAL RESOURCESREDUCTION in the use of NON-RENEWABLE

-

NO CONTAMINATIONfrom the soil is released into the environment

- A total of approx. 400 Lane-Km has been executed so far in the states of Andhra Pradesh, Telangana, Kerala, Andaman & Nicobar Islands, Uttar pradesh, Bihar & Punjab using the Soil Stabilisation/Full Depth Recycling Technology

- The Quantity of Natural Resources saved by VSE for the 400 Lane Km executed so far

- 405 Thousand Cum of Stone Aggregate, equivalent to 30 Thousand Truck Loads!!

EXECUTION PROCEDURE

- In-situ Stabilization of upto 50 cm thick, filled up embankment soil of CBR value > 5% , P.I < 20% by cold in-situ recycling using cement and stabiliser (additive) of required quantity as per design mix.123

- Cement is spread on the embankment soil using a mobile truck mounted Containerized Cement Spreader with Microprocessor-controlled Weighing and Spreading mechanism.

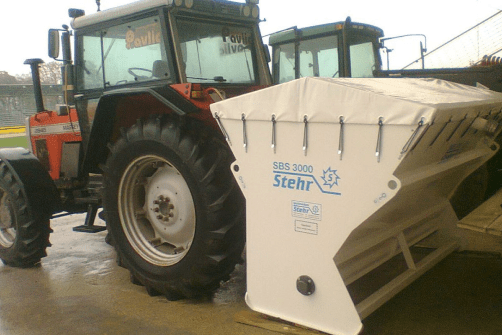

- Additive of desired quantity is spread over with tractor mounted Containerized Additive Spreader.

- The in-situ stabilization for the desired depth is carried out by a Mechanized Recycler.

- The resultant pulverized mix is compacted using a 20 ton Pad Foot Roller and profiled to the required grade, level and thickness using a Grader and rolled with a Smooth Wheel 8-10 ton Tandem Vibratory Roller and Pneumatic Tyre Roller to achieve a Field Density of > 98%.

- The process is completed with curing.

- The pavement achieves an Unconfined Compressive Strength (UCS) value of 4.5 MPa in 28 days.

PRODUCT SPECIFICATION

The Additive is prepared from Natural Minerals by the process of Heating, Grinding and Mixing at a specific proportion. The additive is in powdered form and possesses a self-life of minimum 2 years, when stored in airtight containers. The following are its features.

- Accredited/ approved by IRC/ MoRTH/ MoRD.

- Strength, Durability and UCS values are as per IRC 37, 2018.

- The product satisfies the Toxicology and Leaching Criteria as per the IRC and has been proved Environment Friendly.

- This has been used in Marine environments like Ports, Harbors and Coastal roads for more than 3 years in India.

- Its performance has been validated by IRC, IITs, NITs etc…

- The product has been used in projects under MoRD, NHIDCL and NHAI.

- Our clients have awarded us with High Satisfactory Performance certificates.

- We have the dedicated and skilled engineers/ operators to execute the works with great client satisfaction.

PRESERVING THE ENVIRONMENT

- 01 Km of a 2 – Lane, Rigid Pavement requires 5,719 Cum of Stone Aggregates and 2035 Cum of Sand.

- 01 Km of a 2 – Lane width Full Depth Recycled Pavement requires 843 Cum of Stone Aggregates (equivalent to 60 truck loads), if the traffic is > 20 MSA.

- Adoption of Full Depth Recycling Technology instead of Conventional Rigid Pavement can preserve up-to 4876 Cum of Stone Aggregate and 2035 Cum of Sand, per km for a 2-Lane width road, which is equivalent to 494 Truck Loads.

- About 40,000 Kms of highways have been constructed in the past 5 years.

- Its performance has been validated by IRC, IITs, NITs etc…

- Around 65,000 Kms of highways have been planned in the next 3 years. Going by this rate, another 1,50,000 Kms of Roads can be expected by 2028.

- Total Stone Aggregate Requirement would be approx. 1094 Million Cum.

- If at least 10% of the above roads i.e. 21,500 Kms were executed using this technology, then about 109 Million Cum of Stone Aggregate can be preserved, which is equivalent to 78,26,000 Truck Loads. This is based on the assumption of a 2 – Lane Road.

- This is a rough indicator of saving of Natural Resources in the Country. Click here to Read More.

Approvals and Validation

-

Accreditation by Indian Roads Congress, New Delhi

-

Central Road Research Institute, New Delhi – ApprovalHighly positive conclusions on UCS value, durability, residual strength, elastic moduli and riding quality

-

IIT-Chennai - ApprovalConcluding no impact of leached substances or contamination in the soil and water

-

IIT-RoorkeeMonitoring and ongoing research – Stating high strength, durability, elasticity, cement hydration and no new aggregates needed

-

IITR Lucknow – ApprovalToxins free content in StabilRoad®

-

Research at IIT - Hyderabad and NIT - Warangal

-

VSE’s inhouse testing and support by TEEDE TEHNOKESKUS, Estonia

Traditional Road Construction vs StabilRoad®

Equipment

Excavators